Menu

In the increasingly intricate world of modern electronics, counterfeit chips are emerging as a growing threat to the security and reliability of your systems.

The latest reports from electronics information company ERAI show a worrying increase in counterfeit components as early as 2023, with 786 parts reported as suspicious or non-compliant.

Counterfeit components come in many forms, posing as authentic devices for fraudulent or deceptive purposes, all for profit. This phenomenon affects a wide range of devices, including analog ICs, microprocessors, memory, and programmable logic ICs.

Counterfeiting is not merely an exercise in imitation. In times of supply shortages or when component obsolescence limits availability, the prevalence of counterfeit devices increases, offering suppliers greater short-term profits. Behind the glossy facade of these components lie serious problems that threaten not only your productivity but also your reputation.

Malfunctioning or discarded components masquerading as original products or functionally inferior components sold as superior models create both economic losses and significant operational risks. Falsification of test documents and lack of traceability further exacerbate the phenomenon.

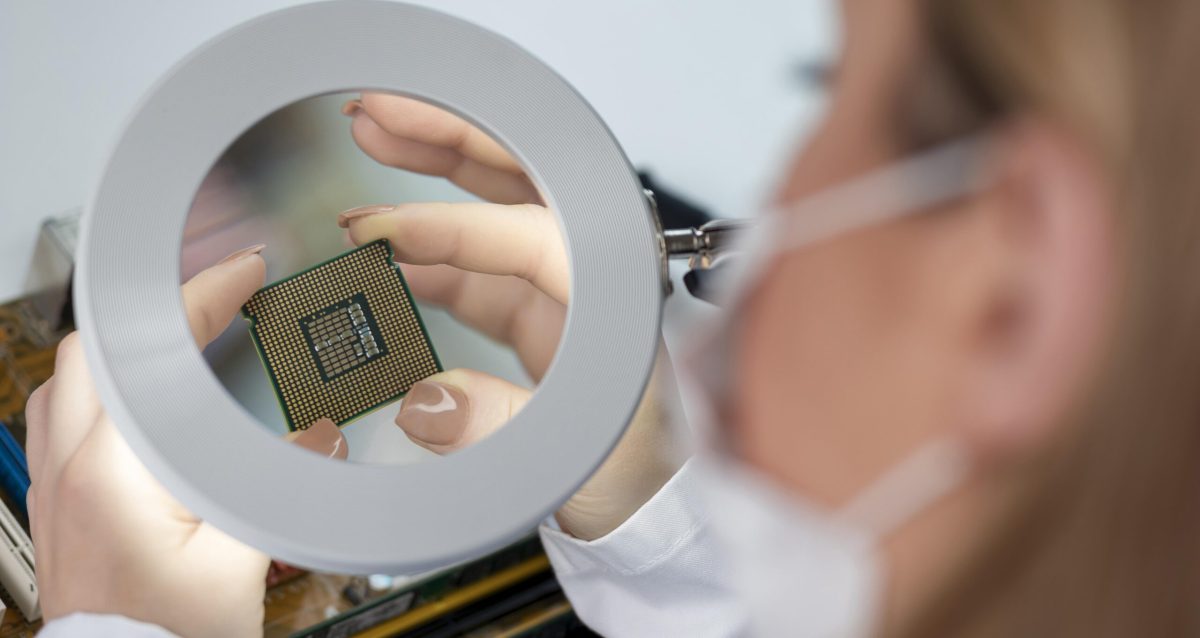

Moreover, the uncertain origins of these components pose additional risks. For example, semiconductors recovered from old boards can suffer catastrophic thermal and mechanical damage; when deployed in new products they can significantly jeopardize the safety and reliability of that product. Even worse, “B Class” or scrap components can also end up on the market and while they may pass basic testing, they can still compromise your production in the long run. To unmask them, avoid electrical circuit failures, and preserve the integrity of your system, you need extremely thorough functional testing that can only be offered by highly equipped specialized companies, such as independent test houses.

The challenge for manufacturing companies is two-fold: they must protect their supply chain and ensure the quality and authenticity of the components they use in their products. However, the fight against counterfeiting is complex and constantly evolving, and requires equally dynamic and cutting-edge solutions.

As independent distributors of electronic components, we offer progressive solutions to our partner customers to successfully address these challenges via a rigorous and holistic approach:

At the core of our business philosophy is a fundamental commitment to ensuring the highest quality of the materials we offer our customers. To this end, we fully recognize and appreciate the benefits of working with independent test houses, external to both our own and our customers’ supply chains. These facilities are completely separate from suppliers and component manufacturers, ensuring neutral, unbiased and conflict-free analysis of product quality and authenticity.

With their extensive experience and expertise in the field, the test houses are able to accurately and promptly identify any discrepancies or anomalies in the components and provide assurances of the genuineness and integrity of the materials. This approach not only reduces the risk of introducing counterfeit products into your systems and production chains but, more importantly, ensures you prioritize material quality in your supply operations.

At Electronic Partner, instead of focusing on order quantity and scale, we are committed to ensuring that every single component meets your rigorous standards of quality and authenticity. Our main goal is to ensure the satisfaction and trust of our customers by providing reliable and authentic products, instead of solely pursuing short-term sales goals. In synthesis, material quality comes before any other business objective for us, and we are dedicated to keeping this promise because we view it as the key factor in creating long-term relationships with our customers.

Our dynamic solutions, which even go beyond the checks performed by manufacturers, prioritize your safety and the reliability of your products. Don’t compromise your productivity or your reputation: choose quality, choose Electronic Partner.

Newsletter archives:

Blog article archives:

Search news articles: